①Conventional electrical protection, leakage protection, short circuit protection, etc. of stainless steel electric heating tube.

② The stainless steel electric heating tube is equipped with multiple interlocking interfaces, which can effectively monitor the oil pump, flow and pressure at any time.

③ The stainless steel electric heating tube electric heating oil furnace is equipped with a set of over-temperature alarm system independent of normal temperature control. When the conventional temperature control is out of control due to various reasons, the system can not only alarm in time, but also turn off the electric heater without resetting to Heating plate manufacturer ensure the safe operation of the system. and input the contact signal.

2 The stainless steel electric heating tube has the characteristics of compact structure, small volume, light weight, simple installation and operation. No pollution when heating, higher working temperature can be obtained under lower working pressure.

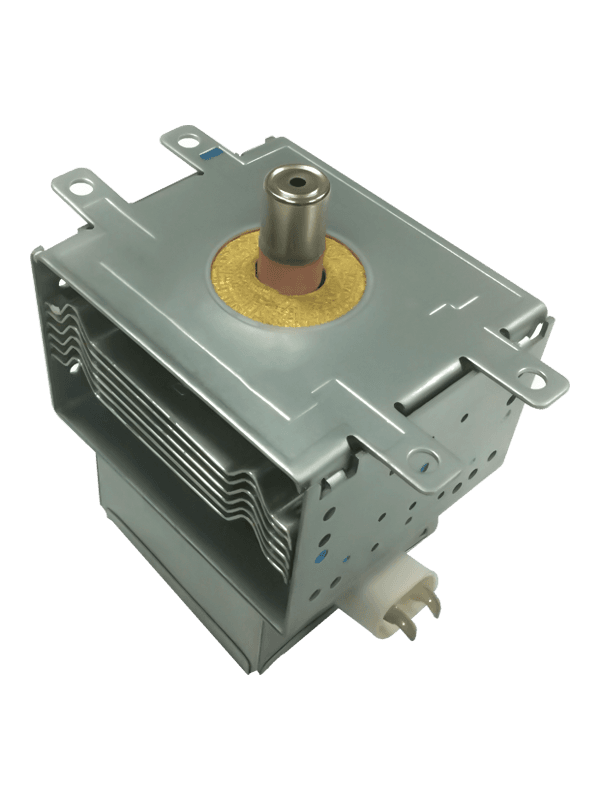

The heating elements used in electric ovens can be roughly divided into three categories:

One is an electric oven that uses a far-infrared tube and a quartz electric heating tube. It is the lower class of all electric ovens and can achieve basic electric roasting functions, but the roasting speed is relatively slow. Therefore, this kind of electric oven is more suitable for families and singles who need to buy electric ovens with general economic conditions.

The second type is an electric oven using two far-infrared tubes and a quartz electric heating tube. This type of oven is characterized by a relatively fast heating speed. However, compared with the former, the price is slightly higher, generally one or two hundred yuan more expensive.

The third type is equipped with an ultraviolet electric heating tube in the accessories, which can be used for high temperature disinfection. Because it can sterilize and disinfect, and the heating speed is fast, the price is relatively high, and it is suitable for consumers with good economic conditions to buy. Electric ovens use the radiant heat emitted by electric heating elements such as electric heating tubes to bake food, but they are also electric ovens. Due to the different types of electric heating elements selected, their functions and prices are also different.

The application of stainless steel on electric heating pipes The instant electric water heater is mainly composed of heating trough plate, pressure sensor, power regulator, water volume regulating faucet, water inlet pipe and water outlet pipe components, among which the heating trough plate is the key of the instant electric water heater. part. The heating tank consists of a tank weight, a sealing ring, a cover and an electric heating element. The electric heating element is located in the groove of the groove plate, which is also generally called the inner tank of the instantaneous water heater. The instant water heater uses a stainless steel electric heating tube as the heating body, and the cold water enters the inner tank and flows directly through the surface of the stainless steel electric heating tube to be heated. Stainless steel electric heating tube is a heating method that is widely used in the instant electric water heater industry.

The advantages of stainless steel electric heating pipes are: good heat resistance, dry burning resistance, relatively mature technology, and relatively low cost. At present, there are many types of stainless steel heating pipes used by various instant electric water heater manufacturers, and the price gap of various pipes is large. The same is the stainless steel electric heating tube, the difference in quality and performance is also very large. The difference between the quality of stainless steel electric heating tube is mainly due to the difference in nickel content. Nickel is an excellent corrosion-resistant material. After combining with chromium in stainless steel, the corrosion resistance and process performance of stainless steel can be improved to some extent. However, in order to obtain a pure austenite structure for low carbon nickel steel, the nickel content should reach 24%, and only when the nickel content is 27%, the corrosion resistance of the steel in some media will be significantly changed. Therefore, in terms of material, 800, 840, and 316L are relatively good corrosion-resistant and high-temperature-resistant stainless steel electric heating pipes. The nickel content of 800 stainless steel pipe reaches 30%, and the nickel content of 840 pipe reaches 20%. Some 304 stainless steels contain as little as 8% nickel. Therefore, it is also very advantageous to use high-temperature and corrosion-resistant stainless steel electric heating pipes with high nickel content.

English

English